Panther - Technocrats, India

- Home

- /

- Panther - Technocrats, India

Introducing Panther, our flagship CNC Metal Plate Profile Cutting Machine, proudly manufactured in India for over 35 years. Panther is a gantry-type, single/dual-drive system engineered for high-precision profile cutting of various metals using either Plasma or Oxy-fuel technology, or both.

Panther: The Ultimate CNC Metal Plate Profile Cutting Machine

The Panther model is designed for robust performance and versatility, offering solutions for a wide range of cutting applications.

Key Features & Capabilities:

- Dual Cutting Technologies: Equipped to operate with both Plasma and Oxy-fuel torches.

- Plasma Cutting: When chosen, it includes our HyCUT 300 Plasma Power Source (30-300 amps, 60 kW output), capable of piercing up to 38 mm and edge cutting up to 50 mm.

- Oxy-fuel Cutting: Utilizes your site's Oxy-fuel cylinder bank for effective cutting.

- "L" Series (Lite Version): We also offer the Panther "L" series, a more basic configuration that comes with essential features, including controllers, hardware, motors, drives, software, and cable drag chains. This series can be supplied with or without a cutting bed.

- Fully Loaded Accessories (Optional):

- Capacitive Auto Height Controller attachment for Oxy-fuel.

- Auto Torch Igniter for Oxy-fuel cutting torch.

- Initial Height Sensing & Auto Height Controller (Model PMT) for Plasma Torch.

- Fume extraction table for a cleaner working environment.

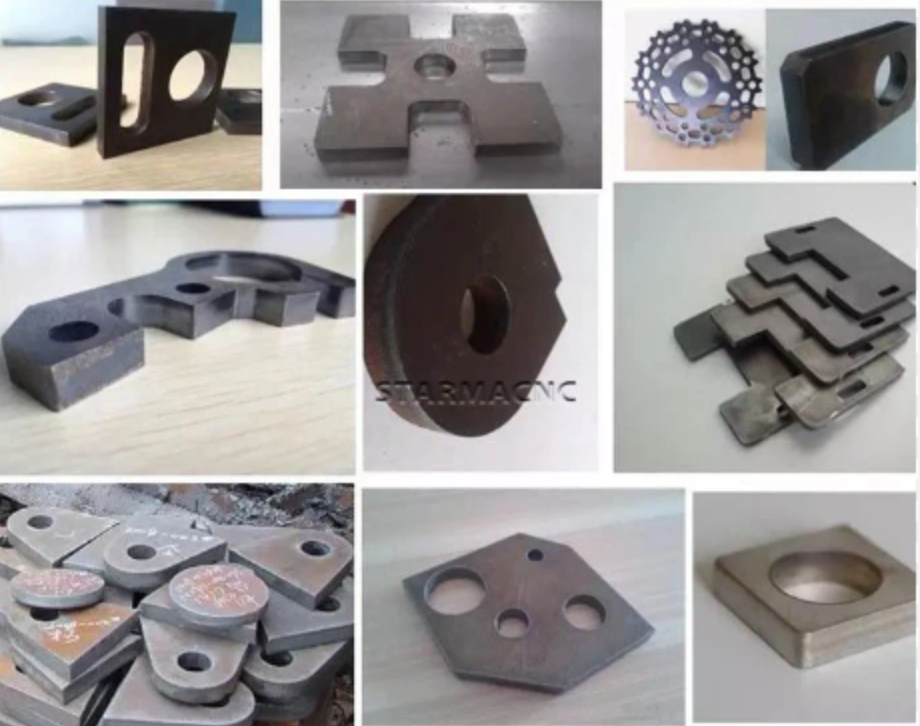

Typical Customer Requirements & Performance:

Panther is engineered to meet demanding industrial needs, handling a wide range of materials and thicknesses:

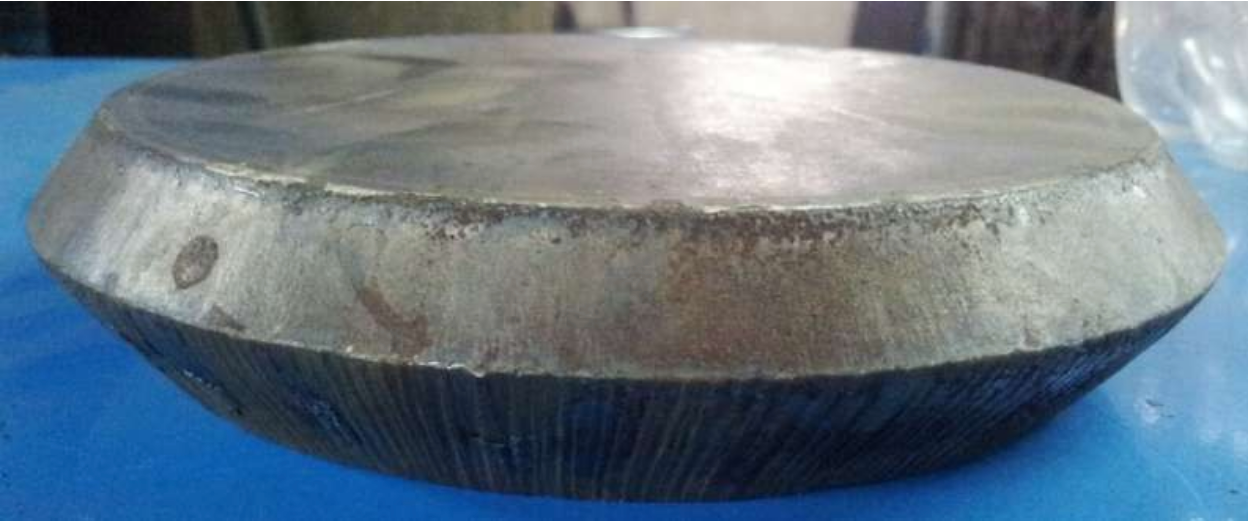

- Material Mild Steel (MS): Capable of cutting from 1 mm to 150 mm with an Oxy-fuel Torch, and up to 50 mm with Plasma.

- Material Stainless Steel (SS): Capable of cutting from 1 mm to 50 mm.

- Large Working Area: Standard plate cutting dimensions are 12.5 meters in length x 2.5 meters in width.

Technical Specifications:

| Items | Technical Parameters |

|---|---|

| Type of Machine | Gantry CNC |

| No. of Torches | 2 (1 Plasma & 1 Oxy-fuel) |

| Working Area | 12.5 m x 2.5 m |

| Machine Area | 13.5 m x 3.3 m |

| Plasma Source | 300 amps Model HyCUT 300 (Water cooled) |

| Plasma Cutting Capacity | Piercing – 38 mm, Edge cutting – 50 mm |

| Oxy-fuel Cutting Capacity (maximum) | 200 mm |

| Structure Material | Hardened and ground rail, specially designed guides, MS Frame |

| No. of Controlled Axes with independent drives | X-axis (2), Y-axis (1), Z-axis (1) |

| Drive Mechanism | Rack & pinion for X1, X2 and Y axis; Ball screw for Z axis |

| Rapid Speed | 12 meters/min |

| Height Control | Initial Height Sensing & Auto height control (Plasma), Automatic torch height control through Capacitive Height Control (Oxy-fuel) |

| CNC Controller Make | FLMC / equivalent |

| Cable Conveyors | Cable drag chain system |

Critical Items and Make:

Our Panther machines are built with high-quality components from renowned manufacturers, ensuring reliability and long-term performance:

| Sr. No. | Description | Make |

|---|---|---|

| 1 | Rack | KHK or Equivalent |

| 2 | Pinion | Technocrats |

| 3 | LM Guides | Hiwin |

| 4 | Gearbox | Delta or Apex or Sesame |

| 5 | Controller | FLMC or equivalent |

| 6 | Servomotor & Drive | Delta or Panasonic or equivalent |

| 7 | Arc Voltage Torch Height Control | Technocrats |

| 8 | Plasma Power Source | Technocrats (HyCUT 300) |

| 9 | Oxy Fuel Torch | Longteng / Harris / TANAKA |

| 10 | Capacitive Height Controller | HYD |

| 11 | Limit Switches | Teknic |

| 12 | Relay Card | Omron |

| 13 | SMPS | Meanwell |

| 14 | Cables | Polycab / Finolex/ LAPP |

| 15 | Relays | Omron/ PLA |

| 16 | Cable Drag Chains | IGUS/ Teknic |

| 17 | Nesting Software | Most 2D / CAD CAM |

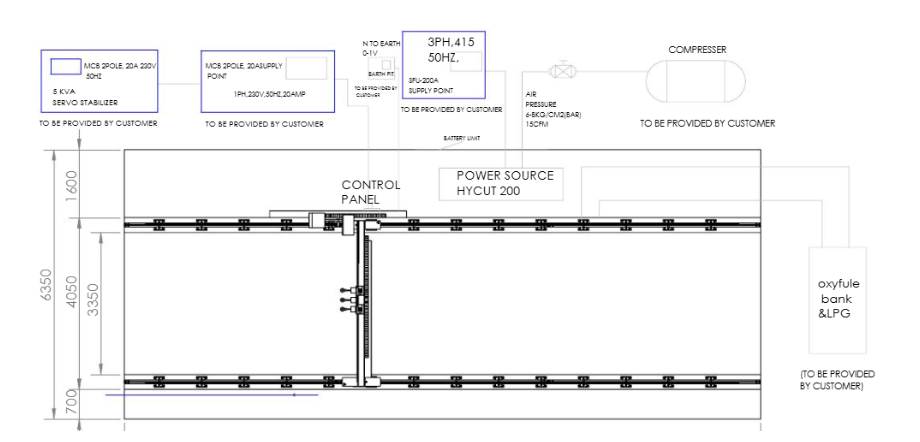

Site Installation Requirements:

To ensure a smooth installation and optimal operation of your Panther machine, please ensure the following site preparations:

- Servo Stabilizer: Required for stable power supply.

- Computer Requirements: Minimum Windows 10 for nesting software compatibility.

- Operator Requirements: Personnel should have working knowledge of AutoCAD, basic computer skills, and English language proficiency.

- Power Supply:

- Three-phase, 415V AC, 150 AMPS supply point with a 3-pole SFU for the plasma power source.

- Single-phase, 230V AC, 20 Amp supply point with a 2-pole SFU for the CNC machine.

- Air Compressor: Clean & dirt-free air delivery at 6-8 kg pressure with a dryer unit. Specifications: Two-stage head (2 cylinders), 200 liters tank capacity, 13 CFM (FAD), 3-phase, 5 hp motor.

- Civil Foundation/Structure: Final GA drawings will be provided for standard civil foundation or structure fabrication.

- Anchoring: Approximately 130 nos. of Chemical Hilti bolts M16x150L (as per site arrangement) are required, assuming RCC flooring.

- Earthing: A separate Earthing pit with neutral to Earth 0-1 volt is mandatory.

- Oxy-fuel System: Customer is responsible for arranging oxygen cylinder bank and LPG cylinders with a proper manifold block for continuous operation.

- Unloading and Storage:

- Unloading Point: Machine and spares must be unloaded at a covered, rain-free, dust-free area.

- Storage: Machine and spares must be stored in a secure, dry, and dust-free environment.

- Installation Site: A roof-top shed with crane facility is required for efficient loading/unloading and smooth machine operation.

- Shop Floor Maintenance: Ensure clear access and sufficient space for machine installation and future maintenance.

Lease / Buy / Enquire

Why Choose us?

- Technocrats Quality: 35-year Indian manufacturing excellence.

- Zero Upfront Payment: Book your machine with no advance till delivery.

- 15-Year Service Assurance (from McLease): Unmatched long-term support.

- Flexible Finance, No CIBIL Check (from McLease): Easy, tailored leasing.

- AI-Powered Remote Support (from McLease): Maximize machine uptime.

- Online Spares & Payments (from McLease): Buy needs, pay your way (PayLater!).

- McLease Ecosystem Advantage: Benefits manufacturer can't directly offer.

"Zero advance changed everything!" - "We needed a new FiberEdge, but upfront costs were a hurdle. McLease's zero advance until delivery was a game-cha ...

Priya Sharma

Proprietor, Apex Metalworks

"No CIBIL, but got financing!" - "Our CIBIL score wasn't perfect, but McLease looked at our order book, not just old records. Their flexible financing ...

Rajesh Gupta

CEO, Fusion Fab Solutions

"Interest-free leasing is true!" - "We were skeptical about 'interest-free,' but McLease delivered. The structured leasing for our new PANUMA was tran ...

Anjali Singh

Operations Manager, Precision Cut Inc.

"15-year service is pure peace!" - "The 15-year service and spares assurance on our McLease ORBITWELD PRO is unmatched. It’s not just a machine; it's ...

Vikram Reddy

Plant Head, Global Structures Ltd.

"RAMC prevents costly downtime." - "Their AI-Powered Remote AMC (RAMC) is genius. We had a potential issue flagged remotely on our FiberEdge, fixed be ...

Suresh Kumar

Maintenance Director, Bharat Heavy Fab

"ETC streamlined our asset data." - "The Equipment Trust Certificate (ETC) service is a fantastic innovation. It gives us granular, verifiable data fo ...

Deepak Jain

CFO, Industrial Equip. Leasing

"Extra liquidity for our loan!" - "We had a bank loan for our CNC, but needed more working capital. McLease's ETC-backed liquidity provided the perfe ...

Meena Patel

Finance Head, Dynamic Engineering

"Multi-vendor choice is fantastic." - "As a B2B marketplace, McLease offers so many machine options. We compared brands, got the best deal, all in one ...

Alok Verma

Procurement Manager, Steelcraft Auto

"Our private label is top-tier!" - "The quality of McLease's private label machines, like our new McLease PIPETIG AUTO WELD, rivals global brands. 'Ma ...

Rahul Mehta

Production Head, Pioneer FabWorks

"Digital platform, seamless support." - "From ordering spares to raising service tickets, McLease's online hub and app make everything so easy. Digita ...

Geeta Rao

CEO, Smart Fab Solutions

"Expanded reach for our machines." - "Partnering with McLease expanded our market reach instantly. Their financing options are a massive selling point ...

Arjun Devi

Sales Director, Machina-Tech India (Vendor Partner)

"Zero investment, pure profit." - "As a McLease channel partner, there's zero upfront investment. We offer their unique financing and earn transparent ...

Sanjay Das

Channel Partner, Eastern Fabricators

"Superior after-sales support." - "We used to dread post-sales issues. McLease's 15-year service assurance and proactive RAMC on our Cerdi have redefi ...

Kiran Nambiar

Workshop Manager, Precision Metal Arts

"Outcompetes fragmented market." - "McLease cuts through the noise of IndiaMart. They don't just give leads; they offer a complete solution that close ...

Neha Sharma

Business Development Lead, InfraFab Ltd.

"A future-proof ecosystem." - "McLease isn't just a product; it's an ecosystem built for the future. Their ETCs, leasing models, and digital support m ...

Gaurav Singh

Strategic Initiatives Head, NewAge Manufacturing

"Customized solutions for complex work." - "Our McLease GANTRYMIG PRO was customized to our exact specs. The attention to detail and integrated suppor ...

Sameer Khan

Lead Engineer, Aerospace Components

"Consumables on time, every time." - "Ordering consumables and accessories online through McLease is effortless. The reliable supply chain ensures our ...

Puja Das

Procurement Officer, Heavy Industries Corp.

"Seamless integration with our needs." - "McLease understood our need for integrated solutions. Their platform seamlessly connects acquisition, financ ...

Amit Shah

CEO, FabTech Innovations

"Trusted hub for industrial buyers." - "Finding trusted vendors for metal cutting machines was tough. McLease has become our go-to hub, offering quali ...

Ravi Kumar

Head of Sourcing, Large Scale Projects

"Productivity Loss Insurance matters!" - "The Productivity Loss Insurance offered by McLease is a huge relief. Knowing we're protected against machin ...

Sunil Yadav

Factory Manager, Production Giants

"McLease is our gateway to quality!" - "Accessing high-quality machines like FiberEdge in Ghana, with transparent financing and strong support from In ...

Kwame Nkrumah

General Manager, Accra Steel Fab (Ghana)

"Reliable spares, even cross-border." - "Getting genuine spares for our McLease machine used to be a headache. With McLease's online support, we get w ...

Ama Konadu

Chief Engineer, Gold Coast Metals (Ghana)

"Flexible financing, truly global." - "McLease's flexible financing is truly global. It allowed us to acquire advanced welding systems without traditi ...

Ahmed Al-Farsi

Managing Director, Desert Fab Corp (UAE)

"Digital convenience, international scale." - "Managing our machine lifecycle through McLease's digital platform is so convenient. It scales perfectly ...

Fatima Khan

Head of Operations, Emirates Heavy Eng. (UAE)

"Strategic partner for Vision 2030." - "For our ambitious industrial projects aligned with Vision 2030, McLease is a strategic partner, offering innov ...

Bandar Al-Otaibi

Director of Procurement, KSA Industrial Dev. (Saudi Arabia)

"Unparalleled local support presence." - "The commitment to 15-year service assurance and the responsiveness of McLease's support, even here in Saudi ...

Mohammed Al-Dossari

Plant Manager, Arabian Metals Works (Saudi Arabia)

"ETC for asset management clarity." - "The ETC provides crucial transparency for industrial asset management, especially when evaluating machines for ...

Abdullah bin Khalid

Chief Investment Officer, Royal Infra Fund (Saudi Arabia)

"Tailored solutions for complex projects." - "McLease's ability to offer customized automated welding systems, like the McLease FINWELD PRO, with comp ...

Noura Al-Hajri

Project Lead, Future City Fab (Saudi Arabia)

"Seamless integration with our ecosystem." - "McLease integrates seamlessly into our procurement and operational ecosystem, offering not just machines ...

Omar Hassan

CEO, Kingdom Precision Eng. (Saudi Arabia)

"Building long-term trust and value." - "Beyond transactions, McLease builds long-term trust. Their commitment to continuous support and innovative fi ...

Khalid Al-Hamad

CEO, Gulf Heavy Machinery (Saudi Arabia)