H-Beam Automated Production Line

- Home

- /

- H-Beam Automated Production Line

Techno-Commercial Proposal

Comprehensive H-Beam Production Line: Assembly, Welding & Straightening System

Prepared for:

Date: June 21, 2025

Prepared by: McLease

1. Executive Summary

McLease is proud to present a state-of-the-art H-Beam Assembly, Welding, and Straightening System, designed to revolutionize your structural steel fabrication processes. This integrated solution, sourced from leading Indian manufacturers with decades of expertise, offers unparalleled efficiency, precision, and automation for H/T beam production.

Our proposal outlines a robust system capable of handling a wide range of beam sizes with exceptional accuracy and speed. Beyond just supplying the machinery, McLease offers a unique value proposition, providing flexible financing options (including lease and buy-back models without CIBIL checks), an industry-leading 15-year service and spares assurance, AI-powered remote maintenance (RAMC), and seamless online support. This ensures not only the acquisition of high-quality equipment but also guaranteed long-term operational uptime and financial peace of mind. Invest in productivity and reliability with McLease.

2. Introduction to the H-Beam Production System

In the demanding world of heavy fabrication, efficiency, quality, and precision in H-beam production are paramount. This integrated system is engineered to automate the critical stages of H/T beam manufacturing – from assembling loose plates and tack welding, to correcting flange deformation post-welding. By incorporating advanced hydraulic and CNC technologies, this solution minimizes manual intervention, reduces production time, and ensures superior beam quality, enhancing your competitive edge.

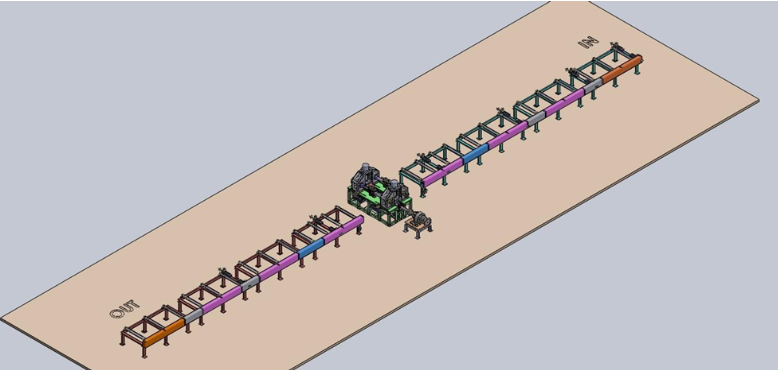

3. System Overview & Components

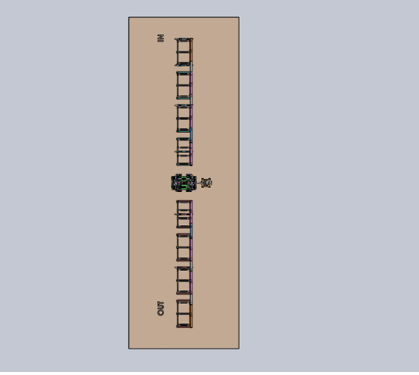

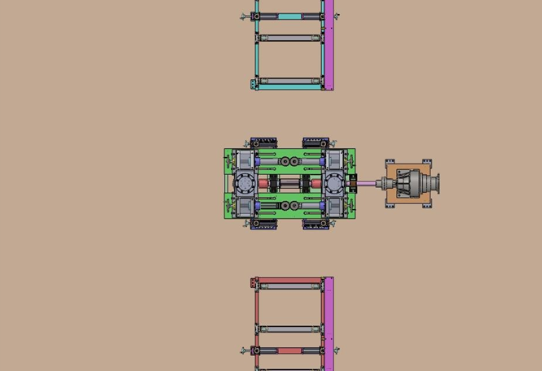

The proposed H-Beam Production Line is a comprehensive, modular solution designed for seamless integration and optimized workflow. The complete system typically consists of the following interconnected subsystems:

- H-Beam Assembly & Tack Welding System: For precise formation and preliminary welding of H/T beams.

- Hydraulic Flange Straightening Machine: Essential for correcting flange deformation caused by welding heat.

- [Optional: CNC Drilling System]: (Can be integrated for automated drilling on beams, if required by client's scope).

Typical H-Beam Requirements Handled:

- Flange Width: 250 mm to 1000 mm

- Web Height: 250 mm to 3000 mm

- Flange Thickness: 6 mm to 60 mm

- Web Thickness: 6 mm to 40 mm

- Beam Length: 6 meters to 12 meters

4. Subsystem Details & Technical Specifications

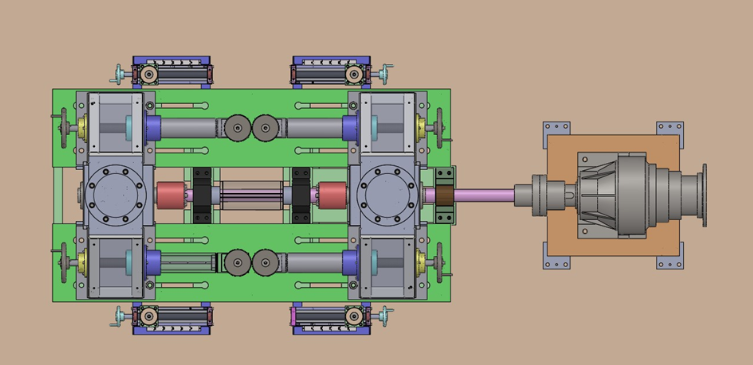

4.1. H-Beam Assembly and Tack Welding Equipment

This machine is specifically engineered for the precise formation and tack welding of H/T beams from individual web and flange plates.

- Operation:

- During assembly, the web and flange plates are centrally and synchronously clamped using powerful hydraulics, ensuring accurate positioning and consistent alignment.

- Automatic centering mechanisms guarantee precise web-to-flange positioning.

- Tack welding is performed efficiently via the MIG process, with programmable time-based weld/skip weld settings for optimal preliminary joint integrity.

- User-friendly operations ensure maximized productivity and simplified maintenance.

- Key Specifications:

- Assembling Speed: Up to 1000 mm/min

- Travel Speed: 650 mm/min to 6500 mm/min

- Hydraulic Pressure (max): 210 bar

- Power: 8.4 KW

- List of Equipment & Sub-Assemblies:

- Beam assembly equipment with web and flange centralizers, beam clamping, and auto tack welding facility: 1 No.

- In-feed conveyor (for loose plates) and out-feed conveyor (for assembled beams in vertical condition): 1 No. each.

- Hydraulically operated web and flange centralizer on the in-feed conveyor: 1 Set – 3 Nos.

- MIG welding power sources (suitable amperage for required thickness): 2 Nos.

- Optional 90-degree tilter (for horizontal welding conversion): 1 Set – 3 Nos.

- Electrical control panel: 1 No.

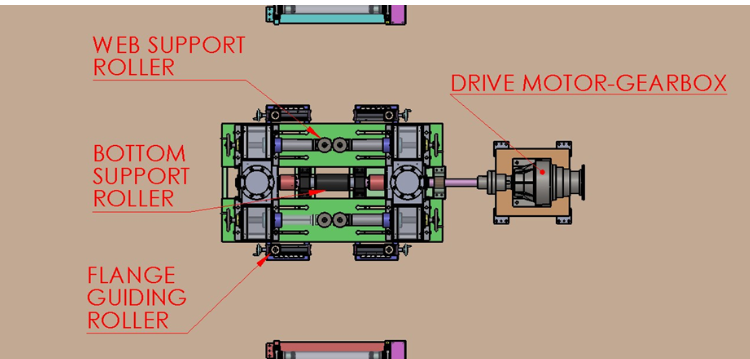

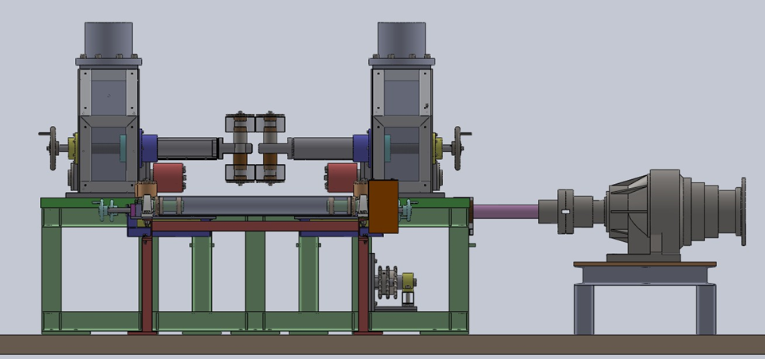

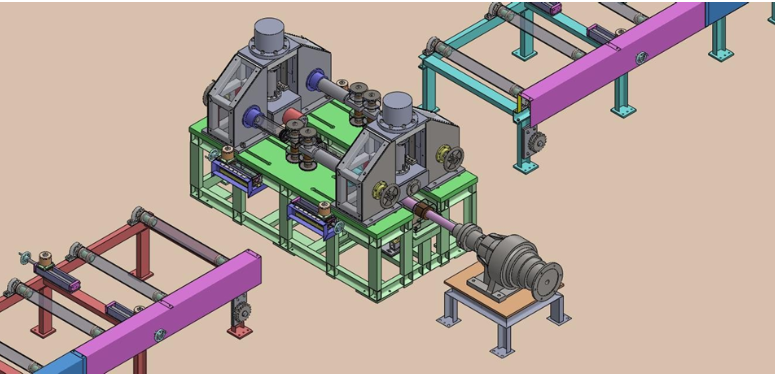

4.2. Hydraulic Flange Straightening Machine

This machine is indispensable for correcting the deformation (flange warping) that occurs in H/T beams after the main welding process due to heat input.

- Operation:

- Designed with sufficient hydraulic capacity to straighten even larger and heavier beams effectively.

- Straightening wheels and drive rollers, crafted from hardened alloy steel, apply precise pressure to restore flange linearity.

- Operated through an intuitive, user-friendly interface for ease of use and optimized straightening speed.

- Key Specifications:

- Flange Width: 200 mm to 1000 mm

- Web Height: 350 mm to 3000 mm

- Flange Thickness: 6 mm to 60 mm

- Web Thickness: 6 mm to 60 mm

- Beam Length: Up to 15 meters

- Straightening Speed: Up to 6 mtrs/min

- List of Modules:

- Hydraulic straightening machine with straightening wheels and drive rollers (hardened alloy steel): 1 No.

- In-feed conveyor: 1 No.

- Out-feed conveyor: 1 No.

- Control panel: 1 No.

5. Operational Advantages & Benefits

Investing in this integrated H-Beam production line from McLease brings a multitude of operational advantages:

- Superior Quality: Automated processes ensure consistent alignment, welding, and straightening, leading to high-quality H-beams that meet stringent industry standards.

- Increased Productivity: High assembling and straightening speeds drastically reduce production bottlenecks, significantly increasing throughput.

- Reduced Labor Costs: Automation minimizes the need for manual handling and adjustment, optimizing labor utilization.

- Enhanced Safety: Automated systems reduce operator exposure to hazardous fabrication processes.

- Versatility: Capable of handling a wide range of H-beam sizes, providing flexibility for diverse project requirements.

- Reliability: Components and designs from established Indian manufacturers ensure robust performance and longevity.

6. Why Choose McLease? Your Unique Value Proposition

While leading Indian manufacturers like Technocrats Plasma Systems Ltd. (a 35+ year old pioneer in machine manufacturing) build high-quality H-Beam machines, McLease offers a comprehensive ecosystem of benefits unavailable when purchasing directly from the manufacturer. Our value proposition extends far beyond the machine itself:

- Zero Upfront Payment: Book your H-Beam machine with no advance payment required until it's physically delivered. Manage your cash flow with unprecedented ease.

- 15-Year Service & Spares Assurance: Experience unmatched long-term peace of mind. McLease guarantees service and genuine spare parts availability for 15 years, ensuring your machine's continuous operation.

- Flexible Finance, No CIBIL Check: Navigate machine acquisition without rigid bank loan requirements. McLease offers tailored leasing solutions based on your repayment capacity and order book, not just CIBIL scores.

- AI-Powered Remote Support (RAMC): Minimize costly downtime with our innovative Remote Annual Maintenance Contracts. Benefit from AI-based preventive maintenance insights and expert remote troubleshooting.

- Seamless Online Support Hub: Easily purchase all genuine spares, consumables, and accessories directly from the McLease.com portal. Manage service requests, track engineer movement, and pay your way (including PayLater options!) all online.

- Proven Indian Manufacturing Quality: Rely on the expertise of 35+ year old Indian machine manufacturers like Technocrats, known for their in-house products, robust designs, and dedication to quality.

- Exclusive McLease Benefits: The comprehensive financial flexibility, unparalleled long-term service guarantees, and integrated digital support platform offered by McLease are benefits that manufacturers alone simply cannot provide directly.

7. Commercial Proposal & Financial Solutions

McLease is committed to providing flexible acquisition models to align with your financial strategy. The indicative cost of a standard H-Beam Assembly-Welding-Straightening machine (depending on specific configuration) is around INR 42 Lakhs.

We offer:

- Outright Purchase: Competitive pricing for direct acquisition.

- Flexible Leasing Options: Tailored lease agreements designed to optimize your capital expenditure and cash flow, potentially structured around your work order potential.

- Buy Back / Sell Back Options: Clauses allowing for future buy-back or sell-back arrangements at the end of the lease period.

- Innovative Financing: Beyond leasing, we can facilitate unique financing solutions that do not require CIBIL/CMR checks, including potential raw material financing.

This H-Beam production line represents a strategic investment that significantly enhances your fabrication capabilities. McLease's comprehensive support model ensures this investment delivers maximum long-term value and operational continuity.

8. Call to Action

Don't let capital constraints or operational worries delay your upgrade!

Contact McLease today to discuss your specific requirements and receive a customized proposal for your H-Beam Assembly, Welding, and Straightening System.

Revolutionize your production with McLease – where cutting-edge machinery meets unmatched support and flexible finance.

Lease / Buy / Enquire

Why Choose us?

- Zero Upfront Payment: Secure your H-Beam system with no advance payment until delivery, easing cash flow.

- 15-Year Service Assurance: Get unmatched long-term peace of mind with guaranteed service and genuine spares from McLease.

- Flexible Finance, No CIBIL Check: Access tailored leasing solutions and innovative financing without rigid bank loan requirements.

- AI-Powered Remote Support (RAMC): Minimize costly downtime with intelligent preventive maintenance and expert remote troubleshooting.

- Seamless Online Support Hub: Easily purchase all spares, consumables, and accessories, and manage service requests 24/7.

- Proven Indian Manufacturing Quality: Benefit from robust designs and decades of expertise from leading Indian manufacturers like Technocrats.

- Exclusive McLease Benefits: Gain comprehensive financial flexibility and integrated digital support unmatchable by direct manufacturer purchases.

"Zero advance changed everything!" - "We needed a new FiberEdge, but upfront costs were a hurdle. McLease's zero advance until delivery was a game-cha ...

Priya Sharma

Proprietor, Apex Metalworks

"No CIBIL, but got financing!" - "Our CIBIL score wasn't perfect, but McLease looked at our order book, not just old records. Their flexible financing ...

Rajesh Gupta

CEO, Fusion Fab Solutions

"Interest-free leasing is true!" - "We were skeptical about 'interest-free,' but McLease delivered. The structured leasing for our new PANUMA was tran ...

Anjali Singh

Operations Manager, Precision Cut Inc.

"15-year service is pure peace!" - "The 15-year service and spares assurance on our McLease ORBITWELD PRO is unmatched. It’s not just a machine; it's ...

Vikram Reddy

Plant Head, Global Structures Ltd.

"RAMC prevents costly downtime." - "Their AI-Powered Remote AMC (RAMC) is genius. We had a potential issue flagged remotely on our FiberEdge, fixed be ...

Suresh Kumar

Maintenance Director, Bharat Heavy Fab

"ETC streamlined our asset data." - "The Equipment Trust Certificate (ETC) service is a fantastic innovation. It gives us granular, verifiable data fo ...

Deepak Jain

CFO, Industrial Equip. Leasing

"Extra liquidity for our loan!" - "We had a bank loan for our CNC, but needed more working capital. McLease's ETC-backed liquidity provided the perfe ...

Meena Patel

Finance Head, Dynamic Engineering

"Multi-vendor choice is fantastic." - "As a B2B marketplace, McLease offers so many machine options. We compared brands, got the best deal, all in one ...

Alok Verma

Procurement Manager, Steelcraft Auto

"Our private label is top-tier!" - "The quality of McLease's private label machines, like our new McLease PIPETIG AUTO WELD, rivals global brands. 'Ma ...

Rahul Mehta

Production Head, Pioneer FabWorks

"Digital platform, seamless support." - "From ordering spares to raising service tickets, McLease's online hub and app make everything so easy. Digita ...

Geeta Rao

CEO, Smart Fab Solutions

"Expanded reach for our machines." - "Partnering with McLease expanded our market reach instantly. Their financing options are a massive selling point ...

Arjun Devi

Sales Director, Machina-Tech India (Vendor Partner)

"Zero investment, pure profit." - "As a McLease channel partner, there's zero upfront investment. We offer their unique financing and earn transparent ...

Sanjay Das

Channel Partner, Eastern Fabricators

"Superior after-sales support." - "We used to dread post-sales issues. McLease's 15-year service assurance and proactive RAMC on our Cerdi have redefi ...

Kiran Nambiar

Workshop Manager, Precision Metal Arts

"Outcompetes fragmented market." - "McLease cuts through the noise of IndiaMart. They don't just give leads; they offer a complete solution that close ...

Neha Sharma

Business Development Lead, InfraFab Ltd.

"A future-proof ecosystem." - "McLease isn't just a product; it's an ecosystem built for the future. Their ETCs, leasing models, and digital support m ...

Gaurav Singh

Strategic Initiatives Head, NewAge Manufacturing

"Customized solutions for complex work." - "Our McLease GANTRYMIG PRO was customized to our exact specs. The attention to detail and integrated suppor ...

Sameer Khan

Lead Engineer, Aerospace Components

"Consumables on time, every time." - "Ordering consumables and accessories online through McLease is effortless. The reliable supply chain ensures our ...

Puja Das

Procurement Officer, Heavy Industries Corp.

"Seamless integration with our needs." - "McLease understood our need for integrated solutions. Their platform seamlessly connects acquisition, financ ...

Amit Shah

CEO, FabTech Innovations

"Trusted hub for industrial buyers." - "Finding trusted vendors for metal cutting machines was tough. McLease has become our go-to hub, offering quali ...

Ravi Kumar

Head of Sourcing, Large Scale Projects

"Productivity Loss Insurance matters!" - "The Productivity Loss Insurance offered by McLease is a huge relief. Knowing we're protected against machin ...

Sunil Yadav

Factory Manager, Production Giants

"McLease is our gateway to quality!" - "Accessing high-quality machines like FiberEdge in Ghana, with transparent financing and strong support from In ...

Kwame Nkrumah

General Manager, Accra Steel Fab (Ghana)

"Reliable spares, even cross-border." - "Getting genuine spares for our McLease machine used to be a headache. With McLease's online support, we get w ...

Ama Konadu

Chief Engineer, Gold Coast Metals (Ghana)

"Flexible financing, truly global." - "McLease's flexible financing is truly global. It allowed us to acquire advanced welding systems without traditi ...

Ahmed Al-Farsi

Managing Director, Desert Fab Corp (UAE)

"Digital convenience, international scale." - "Managing our machine lifecycle through McLease's digital platform is so convenient. It scales perfectly ...

Fatima Khan

Head of Operations, Emirates Heavy Eng. (UAE)

"Strategic partner for Vision 2030." - "For our ambitious industrial projects aligned with Vision 2030, McLease is a strategic partner, offering innov ...

Bandar Al-Otaibi

Director of Procurement, KSA Industrial Dev. (Saudi Arabia)

"Unparalleled local support presence." - "The commitment to 15-year service assurance and the responsiveness of McLease's support, even here in Saudi ...

Mohammed Al-Dossari

Plant Manager, Arabian Metals Works (Saudi Arabia)

"ETC for asset management clarity." - "The ETC provides crucial transparency for industrial asset management, especially when evaluating machines for ...

Abdullah bin Khalid

Chief Investment Officer, Royal Infra Fund (Saudi Arabia)

"Tailored solutions for complex projects." - "McLease's ability to offer customized automated welding systems, like the McLease FINWELD PRO, with comp ...

Noura Al-Hajri

Project Lead, Future City Fab (Saudi Arabia)

"Seamless integration with our ecosystem." - "McLease integrates seamlessly into our procurement and operational ecosystem, offering not just machines ...

Omar Hassan

CEO, Kingdom Precision Eng. (Saudi Arabia)

"Building long-term trust and value." - "Beyond transactions, McLease builds long-term trust. Their commitment to continuous support and innovative fi ...

Khalid Al-Hamad

CEO, Gulf Heavy Machinery (Saudi Arabia)